BOSTON

Manufacturing typically conjures images of dimly lit dirty and dangerous factories crowded with workers, the kind seen in photos of New York City’s garment district in the early 1900s and in some developing countries today. But because of advances in technology, the field of manufacturing—what we make, how we make it, where and by whom—is rapidly changing. As access to technologies continues to pervade our world, the opportunity for everyone and anyone to become a “maker,” inventor, hobbyist or entrepreneur is greatly increased, changing the definition and perception of what it means to be a manufacturer.

Maker Spaces, Fabrication Labs, Hacker Spaces and Tech Shops have been popping up throughout the states and across the globe for several years, democratizing technology, education, art and design with tools such as computer aided design (CAD) software and 3D printers. The buzz has grown so loud around making that the president got involved. Last month, President Obama hosted the first-ever White House Maker Faire celebrating makers, tinkerers, inventors and entrepreneurs, declaring June 18 a National Day of Making. With science, technology, engineering and math (STEM), critical thinking and problem-solving abilities high on the president’s list of skills that must be attained by American youth to succeed in the 21st Century global economy, it is easy to see why Obama would embrace the Maker Movement, which promotes entrepreneurship, creativity, exploration, innovation, failure (yes, it’s OK to fail!), teamwork and self-directed learning.

“Alongside our partners, my administration is getting tens of thousands of young people involved in making,” wrote Obama in a presidential proclamation declaring a National Day of Making. “We are supporting an apprenticeship program for modern manufacturing and encouraging startups to build their products here at home.”

U.S. manufacturing is viewed as crucial to innovation, productivity, jobs, the economy, exports and national security. Obama has championed the manufacturing and “advanced manufacturing” sectors as viable, rewarding career paths for Americans, launching a plan to create a network of up to 15 regional Institutes for Manufacturing Innovation (IMIs) as part of a National Network for Manufacturing Innovation (NNMI).

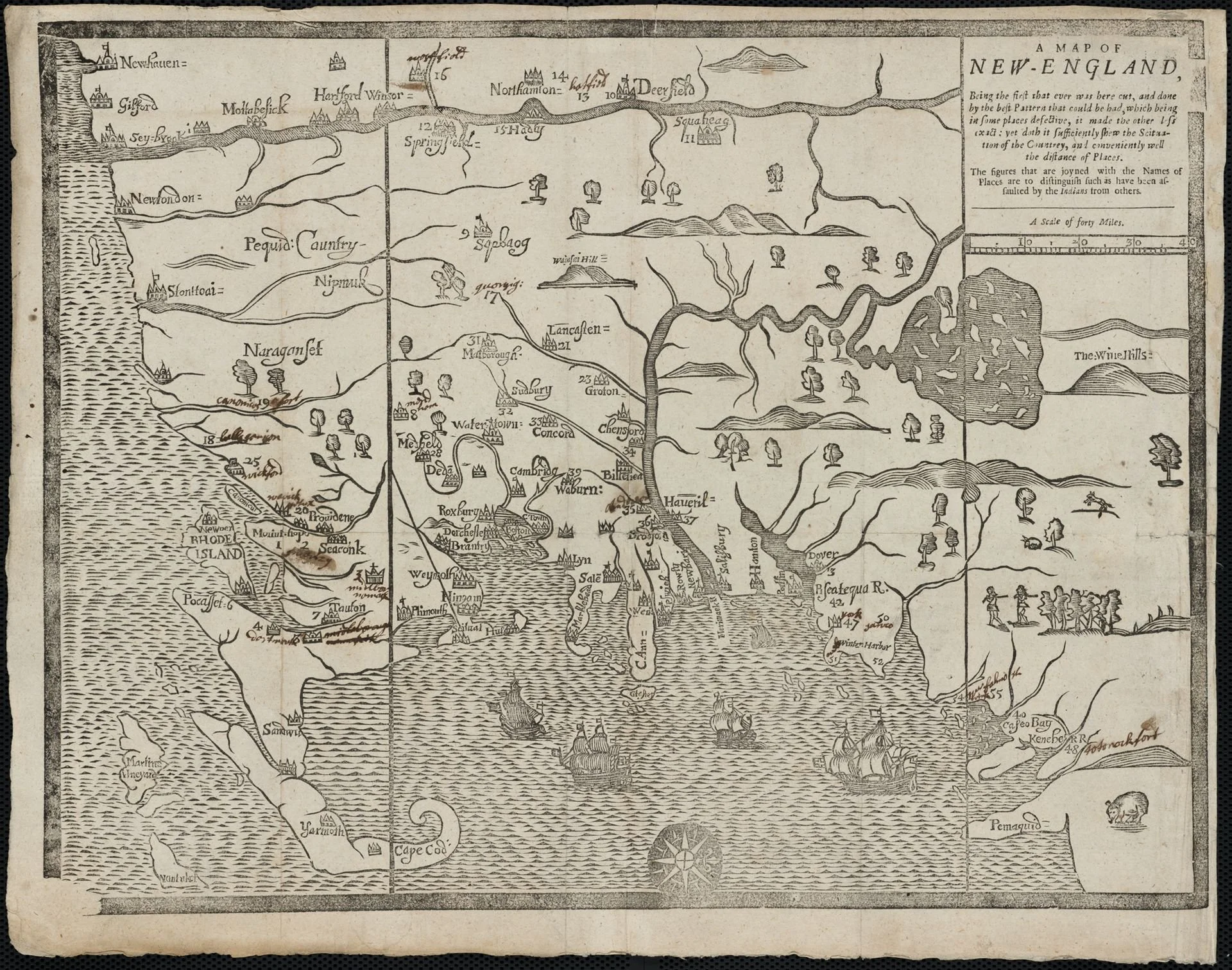

For New England—a historical manufacturing hub that lost 60% percent of its manufacturing jobs over the past three decades—the return of American manufacturing along with the demand for advanced manufacturing solutions is a critical growth opportunity for the region, according to James Brett, president and CEO of the New England Council (NEC).

The region is not alone. A 2011 report conducted by the Manufacturing Institute and Deloitte Consulting indicated that 600,000 manufacturing jobs had gone unfilled nationwide, while 80 percent of manufacturers interviewed for the report anticipated an increase in vacancies in senior-level staffing due to the retirement of Baby Boomers.

NEC reports that despite the decline in manufacturing jobs across New England, Vermont, New Hampshire and Connecticut now boast manufacturing concentrations, or clusters, far exceeding the national average. And with the region’s strengths in education and research, Brett posits that New England is well-poised for resurgence in the sector, and particularly in advanced manufacturing, which has been defined as “manufacturing that entails rapid transfer of science and technology into manufacturing products and processes.”

A poll by Northeastern University as part of the report the Innovation Imperative: Enhancing the Talent Pipeline, released in April 2014, found that the vast majority of C-Suite executives surveyed believe that colleges and universities should expand opportunities for experiential learning (97 percent) and teaching about entrepreneurship (89 percent). Faced with industry’s concerns that college graduates are ill-prepared to enter the workforce, many institutions of higher education are embracing industry partnerships, while companies view investing in education as a direct action they can take to prepare future employees.

To this end, the New England Board of Higher Education (nebhe.org) has been forging industry-education connections for over a decade. Through its Professional and Curriculum Development program, NEBHE has partnered with industry since 2006 to develop problem based learning (PBL) curricula with companies in optics and photonics, sustainable technologies, and advanced manufacturing. NEBHE’s Problem Based Learning (PBL) Projects, funded by the National Science Foundation’s Advanced Technological Education program, turn real-world problems that partner companies actually faced into multimedia case studies called "Challenges” used in secondary and postsecondary STEM courses across the U.S. The PBL Projects conduct professional development workshops with groups of high school and college STEM faculty, teaching teachers how to implement PBL in the classroom. Access to the PBL Projects’ Challenges is free and open-sourced.

Students of PBL become active participants in their own learning as they encounter new and unfamiliar learning situations where problem parameters are ill-defined and ambiguous—just like in the real world. When using the PBL approach, learning occurs collaboratively in small groups, problems are presented before any formal preparation has occurred (the problem itself drives the learning) and new information is acquired via self-directed learning. Research shows that compared with traditional lecture-based instruction, PBL improves student understanding and retention of ideas; critical thinking and problem-solving skills; motivation and learning engagement; the ability to work in teams; and the ability to transfer skills and knowledge to new situations.

NEBHE'S Advanced Manufacturing Problem Based Learning (AM PBL) project focuses on New England’s advanced manufacturing sector, and has partnered with companies to develop Challenges in advanced quality systems, medical devices, nanotechnology, semiconductors and sheet-metal fabrication.

“Problem based learning is such an important aspect of career development and skill development, and it’s not something that is fully utilized in classroom settings,” said Kelli-Marie Vallieres, president and CEO of Sound Manufacturing, in Old Saybrook, Conn., an AM PBL Challenge partner on a sheet-metal fabrication problem.

“Students don’t always understand the practical aspects of what they’re learning—like how important the math is connected to what they are actually going to do in the workforce,” said Vallieres. “Without problem based learning, that disconnect continues, and it impedes the interest that some people have to move into certain careers.”

If we are to pursue a national mantra that says we must graduate global citizens and 21st Century learners, then educators need to graduate to a style of 21st Century teaching, leaving behind our one-size fits all, sage-on-the-stage approaches. In an age when students can access any information they choose from the palm of their hand, teachers are becoming valued more as mentors and guides than absolute fountains of knowledge.

The amount of knowledge available coupled with greater accessibility to information makes it even more imperative that educators connect what students are being taught in the classroom to the real world. This is exactly the reason that problem based learning is successful. Not only do students drive their own learning, they are exposed to new concepts, careers and real-world applications while gaining the skills needed to become lifelong learners who can succeed in a variety of fields.

“One challenge we have, as a growing technology company in a really high-growth industry, is hiring,” said Jamie Beard, counsel and director of operations for FastCAP Systems, a Boston-based AM PBL partner with whom the project developed a Challenge around manufacturing high-powered batteries using nanotechnology. “We can hire associate degrees, we can hire master’s degrees, undergraduate degrees, PhDs. We can use all of those types of people, but the one thing that they need to have is a broad science, technology, and engineering background and a good foundation of math.” She praised the program for getting kids “excited about science, technology, engineering and math,” noting those skills will underlie “the jobs of the future.”

Heather Dunn, senior director of special programs at CIRTEC Medical Devices, another AM PBL Challenge partner, echoed the sentiment: “From CIRTEC’s perspective, because we need good quality, technical personnel, anything that we can contribute to science education, and particularly local science and engineering education, is valuable to us.”

The project developed an AM PBL Challenge with CIRTEC in East Longmeadow, Mass., on dramatically increasing production of a power pack used in a lifesaving implantable medical device.

To see more of what Kelli, Jamie, Heather and other AM PBL Challenge partners had to say about the value of industry-education partnerships, visit the PBL Projects Gallery.

The Challenges developed with NEBHE’s industry partners were first used with participating educators at the AM PBL project’s weeklong professional development Institute at Boston University’s Photonics Center. Thirty-three STEM educators and teacher education faculty members from each of the six New England states were selected through a competitive process to participate in the Institute. More than half participate with a partner at a secondary or postsecondary institution to promote pathways to higher education and careers in STEM for their students.

Of course, NEBHE is not the only institution working directly with advanced manufacturers. The Connecticut College of Technology’s Regional Center for Advanced Manufacturing develops and provides resources to educators and students interested in learning new technologies in manufacturing. New Hampshire’s Advanced Manufacturing Partnerships in Education (AMPed) is also an example of a statewide program developing curriculum and training to prepare students to enter the growing advanced manufacturing sector. In Massachusetts, the online resource AMP it up! informs students, parents, guidance counselors and other stakeholders about the state’s burgeoning advanced manufacturing sector and the jobs available to graduates. Support for these kinds of direct connections between education and industry will lead to an increase in STEM, critical thinking and problem-solving skills, and students’ pursuit of STEM careers.

Ultimately, no one knows the current and future needs of industry better than industry members themselves, making it imperative that advanced manufacturers and other STEM professionals continue to work with educators to develop curriculum, provide guidance and opportunities for students and teachers that will make STEM education relevant, while preparing students to succeed in the ever-changing workplace of tomorrow and today.

Nicole Schepker is project coordinator for the PBL Projects.