Mixing it up in Lynn

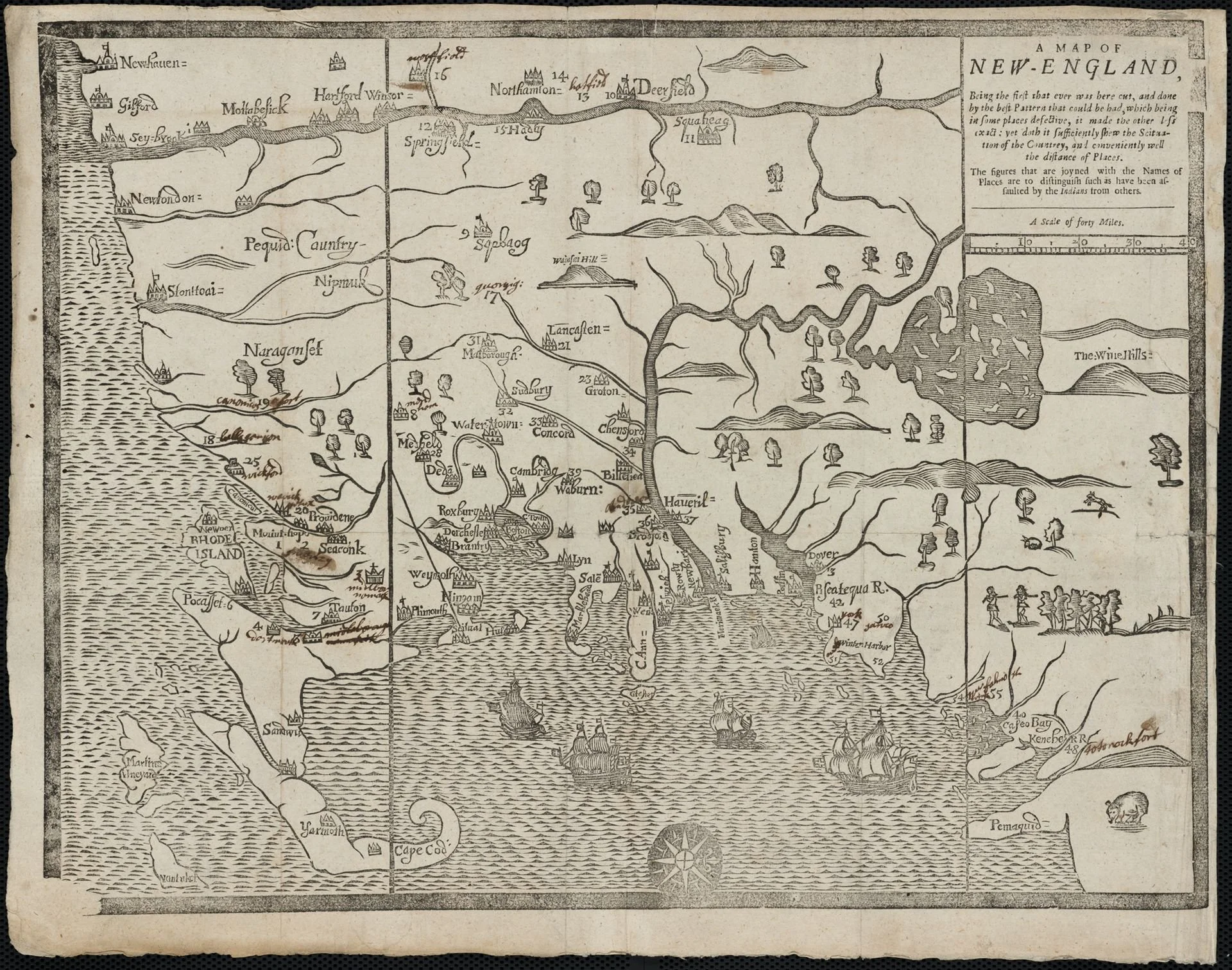

Delightfully bizarre view of Lynn, Mass., in 1881. It was a major manufacturing center, especially of shoes.

“I grew up about 30 minutes north of Boston in a town {Lynn, Mass.) that was a virtual melting pot - I was exposed to all different backgrounds, cultures, and religions, fueling my personal interests in global issues.’’

—- Alex Newell, (born 1992) , actor and singer

Alex Newell in 2015

We still make 'em

New Balance running shoes

Early 19th Century shoemaking shop displayed at the Maine State Museum, in Augusta

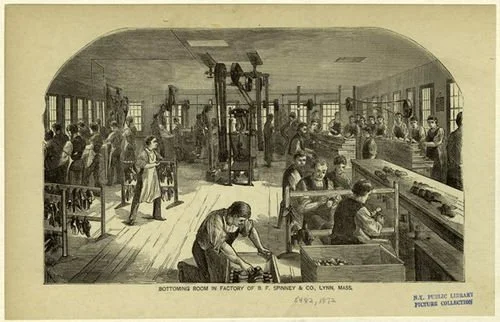

By the mid to to late 19th Century, the shoemaking industry had migrated to the factory and was increasingly mechanized. Here’s the bottoming room of the B. F. Spinney & Co. factory, in Lynn, Mass., in 1872

The shoe industry was once huge in New England. It was concentrated in eastern Massachusetts, particularly in Lynn and Brockton, but Maine and New Hampshire had shoemaking centers, too. And some of the companies that served the industry were big, too— most notably United Shoe Machinery Corp., based for decades in its Art-Deco skyscraper on Federal Street in downtown Boston. But by the mid-20th Century, much of the industry had moved south, in search of cheaper labor. But a few shoe companies remain in the region.

The following is edited from a New England Council report:

“New Balance, the Boston-based footwear maker, opened manufacturing facilities in Skowhegan, Maine, and Londonderry, N.H., as part of its efforts to expand U.S. manufacturing capacity. The company aims to enhance its American supply network through innovation, automation] and robotics.

“With the $65 million Skowhegan expansion, New Balance will add a 120,000-square-foot single-story addition to the existing facility, doubling production capabilities and creating 200 new jobs. Additionally, the Londonderry facility would cover 102,418 square feet and includes office and manufacturing space, seven loading docks, and LED lighting. New Balance expects to hire 250 employees initially and up to 450 upon completion of the project.

“‘ New Balance has always been strongly committed to the communities where our associates live and work,’ said Raye Wentworth, director of domestic manufacturing at the company. ‘We’re thrilled to be able to support this important opportunity to add quality, affordable education and child-care resources for local families.”

An ad for the long-gone, high-end Brockton, Mass.-based shoemaker the Geo E. Keith Co., whose famous trade name was Walk-Over

#New Balance

#shoemaking

Yes, plenty of shoes are still made in New England

New Balance trail running shoes

Edited from a New England Council (newenglandcouncil.com) report.

“New Balance, the athletic-shoe company, is expanding with a new facility in Methuen, Mass. This factory was opened with Gov. Charlie Baker, U.S. Rep. Lori Trahan and local leaders, to participate in the grand opening of New Balance’s newest manufacturing hub.

“The 80,000-square-foot facility opened for business in January after $20 million in renovations, according to the company. The factory currently employs more than 90 associates producing the brand’s MADE 990v5 running shoe, with plans to more than double the current workforce and production capabilities by the end of the year. Including the new New Balance factory in Methuen, New Balance owns five manufacturing facilities in Maine and Massachusetts where about 1,000 U.S. workers prepare, cut and mold athletic-shoe materials and components and then sew, press and assemble into the final product.

“Manufacturing has always been an important part of our company culture,” said Joe Preston, New Balance president and CEO. “Our associates have proven that high-quality athletic footwear can be produced in the U.S. Their skilled craftsmanship and dedication to continuous improvement will help us meet our significant U.S. and global consumer demand and drive our continued business growth.”

By the late 19th Century, the shoemaking industry had migrated to the factory and was increasingly mechanized. Pictured, the bottoming room of the B. F. Spinney & Co. factory in Lynn, Mass., in 1872.